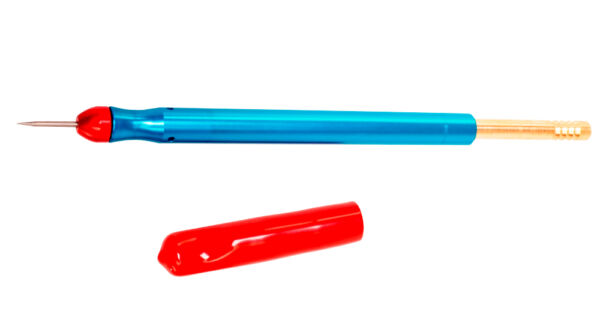

Description

Hardened steel replacement point tip for slide hammer and spring hammer (0.060 inch diameter). Keep an extra Hardened Steel Replacement Point in your tool box.

From the Archives

Using the Slide Hammer as a Glass Probe

As a probe, use the sharp end of the Slide Hammer to remove loose glass fragments. Also works well to remove dust and other contaminates from the pit area of a stone damaged windscreen. This procedure only takes a few seconds and perform before beginning each and every windscreen repair.

As a mini bull’s-eye maker insert the Slide Hammer into a small drill hole at the end of a long crack. For best results the drill the hole using the Delta Kits .047 Carbide Bur to a depth of approximately 1.5 mm (2/3rds through the outer layer of glass). With the tool held at a 90-degree angle to the glass, insert the point of the Slide Hammer into the hole and hold firmly against the glass at the bottom of the hole with one hand. Use the other hand to raise the brass hammer approximately 7 cm.

With a slight throwing motion, the hammer slides back into the receiver until it comes in contact with the receiver’s bottom. As the hammer impacts the bottom of the receiver, the point drives deeper into the drill hole creating a small bull’s-eye.

Practice Makes Perfect

Always use in accordance with the manufacturer’s instructions the Delta Kits slide hammer is much safer than other tools used for this purpose and provides more consistent results.

With a hole of the proper size and depth, most technicians find that little or no practice is necessary. Make a perfect bull’s-eye every time. However, Delta Kits recommends practicing a few times on a scrap piece of laminated glass or an old windscreen. Get comfortable with the tool.

Nathon S. –

Nice to have this part available to purchase without buying it all new.