Description

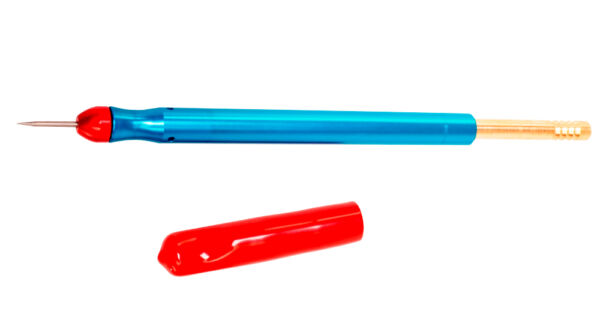

Not your ordinary rubber band. This hardened steel ball is used to create bull’s-eyes in laminated practice glass. Don’t be fooled by soft steel Bull’s-Eye Maker imitations that flatten with every blow. This simple Bull’s-Eye Maker tool will last indefinitely when used according to instructions.

From the Archives

Ring Around the Bull’s-eye

Pressure Ring or Trapped Air?

A recent post on windscreen-repair-forum.com brought to my attention that even some experienced windscreen repair technicians are confused about the cause of the ring around the outside of a bullseye, which is sometimes visible after the completion of a windscreen repair. It’s time to separate the facts from the fallacy.

To be fair, there are several possible causes for a ring around a bullseye, and understanding the cause is the key to identifying what you are seeing. In this three part series, we will explore the primary causes.

A pressure ring is translucent; it has no color, and has a bit of a watery look to it. What you see is the injection resin between the glass and the Polyvinyl Butyral (PVB). Causes include:

Excessive pressure.

Forcing resin into the damage under excessive pressure, it can separate the PVB laminating material from the glass.

- “Flowering” or “the daisy effect” is this form of separation or delamination of the glass. If the damage is severe enough the injection resin may end up between the PVB and the glass resembles the shape of a flower. On a bull’s-eye it is typically a symmetrical ring “pressure ring,” around the outside of the damage. On a crack or star break it will generally follow the shape of the damage with just a fine watery looking line.

- It does not take a great deal of pressure to inject resin into most damage, and very little pressure to fill a bullseye. Do not use more pressure than necessary and avoid the use of injectors advertised as “high pressure.”

Excessive heat.

- Heat causes the PVB to soften, allowing the injection resin under pressure to separate the glass from the PVB.

- Adjust glass and resin temperatures to the Delta Kits recommended range of 70° – 90° Fahrenheit before starting a repair whenever possible. If the glass is warmer than the recommended temperature range, start with less pressure than normal.

Old glass.

- Over time the glass layers will begin to separate from the PVB layer between them. Most often beginning with the edges of the glass where the PVB is open to the air. Also, while this is very common in vehicles that are over 10 years old, the delamination process may actually start much sooner… Continue Reading

Alexei B. –

We need this product for training. Very important thing! With it, we train better.

Leonard H. –

Makes the best bulls-eye and half moon breaks.