Description

At the heart of every great windscreen repair system there is a great injector. The exclusive spring-loaded Delta Kits I-100 Spring-Type Stainless-Steel Injector is preferred by auto glass repair and replacement professionals worldwide. You won’t find a finer Spring-Type Stainless-Steel Injector at any price!

- Easy to use and clean

- Low maintenance (one end seal)

- Ergonomic comfort grip lift knob

- Super durable polished stainless steel

- Lightning fast vacuum/pressure switching

- Spring-loaded mechanism for superior pressure control

- Beefy oversized upper plunger for exceptional durability

- Minimal resin loss with Delta Kits’ precision threading

- Exclusive industry-leading injection molded Delta Kits end seal design

- Oversized upper cylinder allows use of eyedroppers and syringes for resin conservation

- Industry-leading Delta Kits limited lifetime warranty

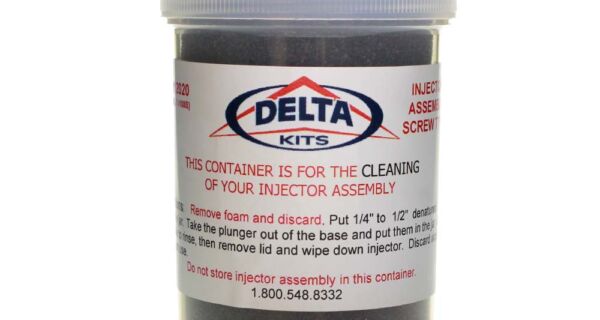

- 22435 Cleaning Jar and Cap included

Replacement Parts:

12010 I-100 Injector Plunger, Spring Type

12040 I-100 Injector Body, Spring Type

From the Archives

How to Maintain the I-100 Spring-type Resin Injector

Failure to properly clean the injector can make it inoperable. If your injector becomes cured, which bonds the parts together making it stuck, please contact Delta Kits.

Typically, during the summer, we get a number of calls from technicians who have cured their injectors. The cleaning process is simple, but must be performed properly and consistently.

First, separate the piston from the cylinder immediately after use, and lock the piston in the vacuum position. A fully functioning I-100 injector should slide back and forth smoothly and evenly with ease.

Then, rinse both parts thoroughly with denatured alcohol.

Now, remove the parts from the denatured alcohol and set the piston back into the pressure position. Rinse the parts thoroughly once again.

Blow dry or wipe dry with a paper towel. If you use canned air, make sure it’s a type that doesn’t have a lubricant in it.

Store the piston and cylinder separately in your Delta Kits toolbox with the piston in the pressure position. Be sure to keep the lid closed to reduce UV exposure. Failure to properly clean your injector voids the warranty, so please take the extra two minutes to clean your injector after each windscreen repair. With proper maintenance, your Delta Kits injector will last a lifetime.

Most importantly, an injector can cure when resin residue is left inside and then exposed to UV light, which hardens the resin. This essentially bonds the injector together, not allowing it to slide back and forth.

Above all, it is no longer fully functional as it cannot be pulled up into a vacuum cycle. As a matter of fact, it is no longer able to do a proper repair.

Reviews

There are no reviews yet.