The Slide Hammer is a versatile tool that is used to create mini bulls-eyes at the end of long cracks in automotive glass, but also makes an excellent probe for cleaning the impact point of a break.

Below are operating instructions for the Delta Kits Slide Hammer

Below are operating instructions for the Delta Kits Slide Hammer

The Slide Hammer is a versatile tool that is primarily used to create mini bulls-eyes at the end of long cracks, but also makes an excellent probe for cleaning the impact point of a break. Although long cracks can be filled without first creating a termination point, resin injected into the crack under pressure can often cause the crack to grow. Mini bulls-eyes are used as an effective termination point to help stop long cracks from spreading during the resin injection process, and also provide a pool of resin at the end of the crack to assure the crack is filled to the very end.

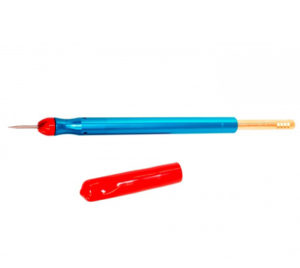

The Slide Hammer is made up of 5 primary components.

1) Create a perfect 2 mm to 3 mm mini bulls-eye every time with the hardened steel, tapered and sharpened, precisely angled point.

2) The red aluminum tip is fitted with a special magnet that holds the point in place but allows for easy removal and replacement.

3) The blue aluminum receiver tube has and ergonomically shaped finger grip on the tip end and a hole in the other end to allow insertion of the hammer.

4) The solid brass piston “hammer” is precisely machined and weighted for easy gripping, smooth operation and is fitted with a small steel insert that works with the magnet to keep the hammer from sliding out of the receiver when not in use. The magnetic pull on the hammer helps provide control when the tool is being used to create a mini bulls-eye.

5) The red plastic cap covers the point to protect the sharp tip from accidental damage, and consumer safety. Please replace the protective cap after each use.

Using the Slide Hammer as a Glass Probe

As a probe, the sharp point of the Slide Hammer is used to remove loose glass fragments as well as dust and other contaminates from the pit area of a stone damaged windscreen. This procedure only takes a few seconds and should be performed prior to beginning each and every windscreen repair.

As a mini bulls-eye maker the Slide Hammer is inserted into a small hole drilled at the end of a long crack. For best results the hole should be drilled using the Delta Kits Tapered .047 Carbide Bur to a depth of approximately 1.5 mm (2/3rds through the outer layer of glass). With the tool held at a 90-degree angle to the glass, the point of the Slide Hammer is then inserted into the hole and held firmly against the glass at the bottom of the hole with one hand, while using the other hand to raise the brass hammer approximately 7 cm.

With a slight throwing motion, the hammer slides back into the receiver until it comes in contact with the receiver’s bottom. As the hammer impacts the bottom of the receiver, the point is forced deeper into the drill hole creating a small bulls-eye.

When used in accordance with the manufacturer’s instructions the Delta Kits slide hammer is much safer than other tools used for this purpose and provides more consistent results.

With a hole of the proper size and depth, most technicians find that little or no practice is necessary to make a perfect bulls-eye every time, however Delta Kits recommends practicing a few times on a scrap piece of laminated glass or an old windscreen to get comfortable with the tool.

1) For a smaller bulls-eye, use less force when engaging the hammer and/or slightly decrease the drill hole depth.

2) If using the tool as instructed does not produce a bulls-eye or a larger bulls-eye is desired, increase the drill hole depth and/or use slightly more force when engaging the hammer.

Caution: Drilling too deep may result in damaging the laminate. If you accidentally drill all the way through the first layer of glass, stop immediately, and do not use the slide hammer or damage to the second layer of glass may occur.